The challenge

Designing polymers for industry

Polymers are materials consisting of large molecules, composed of many repeating units, used to make everyday products from paint to sunscreen.

Traditional approaches to creating polymers tend to result in a diverse blend of polymers and give little or no control over their molecular structure and properties.

Better control over the polymers created through the RAFT process opens up the opportunity to create new and improved products.

Our response

The RAFT process

RAFT (Reversible Addition-Fragmentation chain Transfer) is a process for making precisely engineered polymers. It can give rise to products with vastly improved performance, which gives companies an important differentiation in the marketplace.

RAFT's applications range from novel drug delivery systems to personal care products, lubricants and coatings.

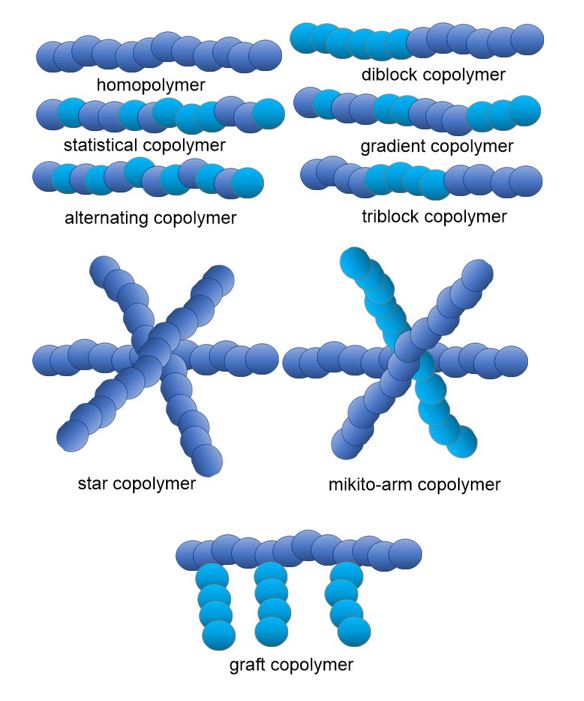

RAFT is a form of controlled free radical polymerisation that enables design of polymers with enhanced properties. RAFT can be used with a wide range of monomers and reaction conditions and gives unprecedented control over polymer size, composition and architecture.

- RAFT polymerization can be performed by simply adding a chosen quantity of an appropriate RAFT chain transfer agent to a conventional free-radical polymerization. The same monomers, initiators, solvents, and temperatures are used

- RAFT polymerization possesses the characteristics usually associated with living polymerization. All chains begin growth at the commencement of polymerization and continue to grow until the monomer is consumed. Molecular weights increase linearly with conversion

- Narrow molecular weight distributions and predetermined molecular weights are achievable

- RAFT polymerization results in reactive terminal groups that can be purposely manipulated to build in additional functionality in the polymer backbone

- Complex architecture, including graft, block, star and gradient polymers are accessible.

The results

A fully integrated service

Our RAFT research team can provide bespoke solutions for polymer design and manufacture.

We provide a fully integrated service, including:

- R&D services

- process development including high throughout facilities

- laboratory through to pilot-scale batch or flow manufacture

RAFT involves the use of chain transfer agents, which are small organic molecules that are responsible for controlling growth. RAFT agents can be purchased from our licensed suppliers: Boron Molecular, Monomer Polymer, Merck and Strem.