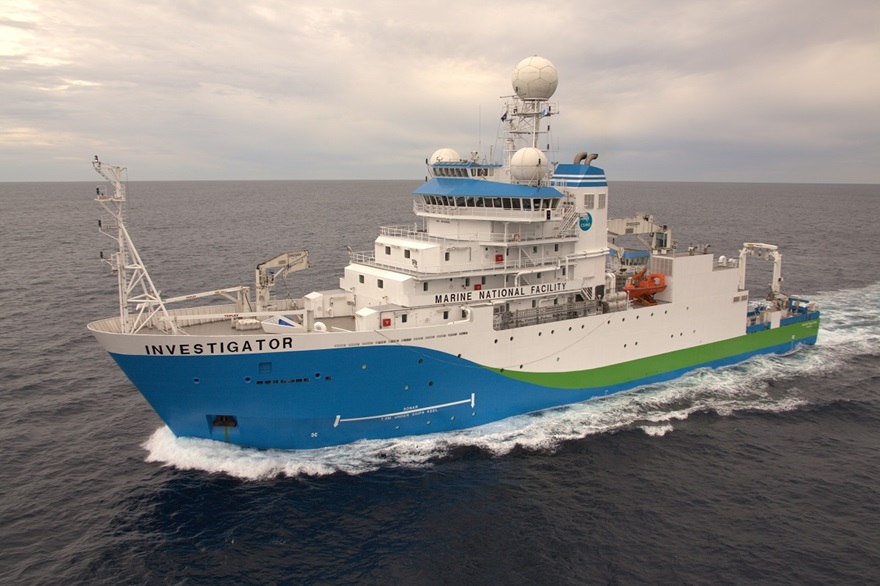

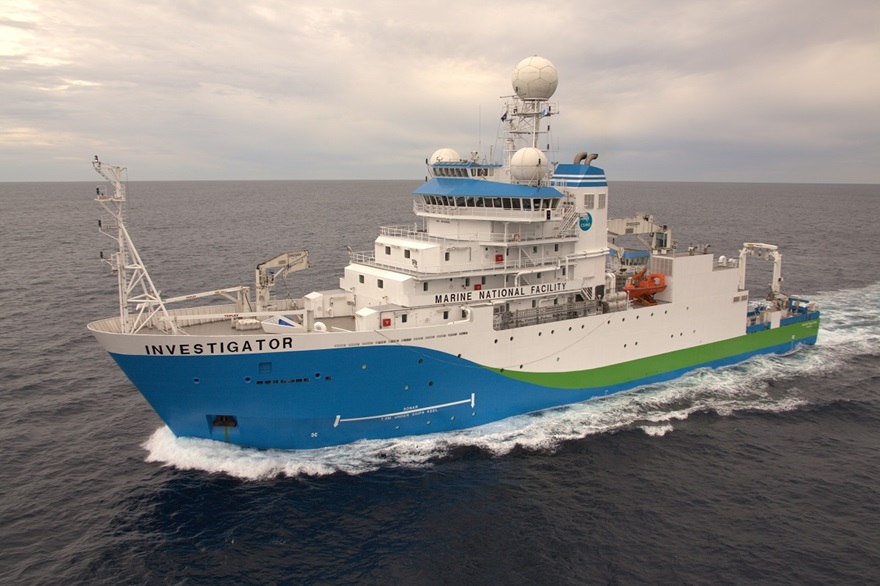

This page may be lost at sea, if only we had the RV Investigator to help find it

Let us help you find what you're after

Tried searching but still no luck? Contact us

This page may be lost at sea, if only we had the RV Investigator to help find it

This page may be lost at sea, if only we had the RV Investigator to help find it

Tried searching but still no luck? Contact us

This page may be lost at sea, if only we had the RV Investigator to help find it

Find out how we can help you and your business. Get in touch using the form below and our experts will get in contact soon!

CSIRO will handle your personal information in accordance with the Privacy Act 1988 (Cth) and our Privacy Policy.