In a world of fast and cheap fashion, the average Australian accumulates 27 kilograms of new clothing each year and throws away a further 23 kilograms. Too often, these garments end up in landfill where the fabric can take hundreds of years to break down. They release a stream of harmful carbon emissions as they do.

The problem is so large that textiles and fashion supply chains have now surpassed the carbon footprints of shipping and international aviation combined. And, according to the World Economic Forum, textiles and fashion supply chains are now the third largest polluter globally.

The question of what to do with the mountains of discarded clothes and fabric we generate is one of our trickiest environmental challenges. But the answers have been in very short supply.

Too many textiles end up in landfill

While many have thrown their hands in the air at this knotty problem, one forward-thinking Australian company has taken its product stewardship responsibilities beyond its own backyard.

Keen to live up to their name, local uniform manufacturers Sustainable Schoolwear started thinking through a circular economy approach for their business in 2019.

Owner Annie Thompson estimated that every school would throw out up to 200 kilograms of uniforms every year. Across the country, this means as much as 2,000 tonnes of uniform waste is making its way to landfill annually.

Ms Thompson said the company had looked around for ways for the uniforms they made to be responsibly disposed of, but found nothing.

She wanted to see if she could find a way to address the problems of textile and plastic waste by creating a new, usable material that combined both.

“Clothes are notoriously difficult to recycle. At the same time less than 10% of the 2.5 million tonnes of plastic waste that Australians generate each year is recycled,” Ms Thompson said.

“We wanted to try to solve both problems at once but there was nothing in the market to do this. So we set about inventing it,” Ms Thompson said.

Setting out on a sustainability mission

Starting out with only a pizza oven and a vision, the team worked for two years to develop a strong and sustainable material made from a combination of textile fibres and recycled plastics.

The result was a finer reinforced composite material which they dubbed ‘FABtec’.

As part of the same mission, Ms Thompson also established a new company, Worn Up, to gather old uniforms from across the country to feed into the recycling program.

Since 2020, Worn Up has diverted more than 100 tonnes of uniform material from landfill by collecting old, worn and torn uniforms from schools across the east coast of Australia.

It also got buy-in from local councils and corporations like Coke and IKEA, which provides unwearable uniform stock for recycling.

Positive proof of concept for fabric reuse

While FABtec showed great promise as a material, Annie knew she would need proof if she was going to attract investment or convince a manufacturer to take it on.

Intent on better understanding the product’s properties and potential applications as well as wanting to make it even better, she reached out to Australia’s national science agency CSIRO and applied for a Kick-Start voucher.

Kick-Start helps innovative Australian start-ups and small SMEs to grow and develop their businesses by providing access to CSIRO’s researchers and capabilities.

Worn Up was successful in gaining matched funding through the program which allowed them to tap into the expertise of CSIRO’s world-class scientists, as well as its advanced facilities and equipment.

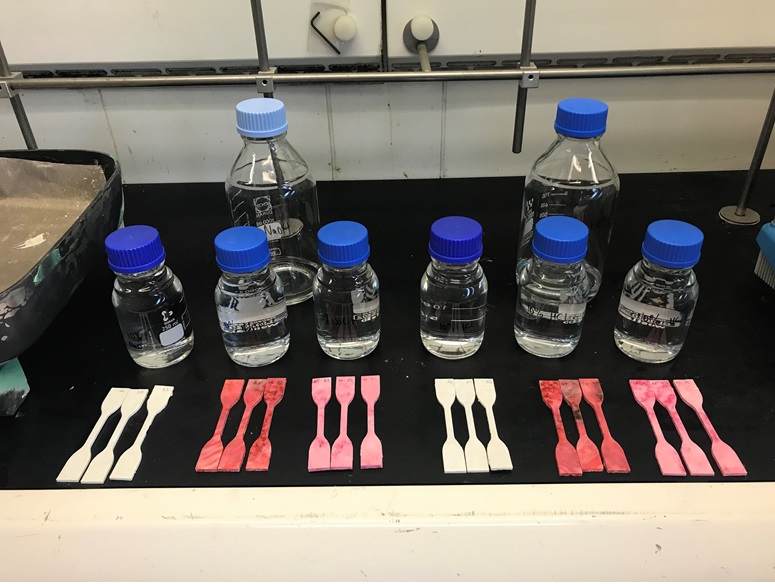

CSIRO Senior Experimental Scientist Mel Dell’Olio said the first task was assessing the existing fabric product.

“FABtec proved to be an innovative compound with many possible applications, but we knew it could be even better,” Mr Dell’Olio said.

“Our scientists spent six months working with Annie and her team to assess the product, look at their long-term goals and see how the formula could be improved.

“Not only did we increase the percentage of fibre in the new formula, but the final product was much stronger as a result.”

Mr Dell’Olio said it was incredibly rewarding to help businesses grow and prosper through the Kick-Start program.

“Annie had the passion and the business smarts she needed to get FABtec to where it was, but she needed the scientific know-how to take it to the next level,” Mr Dell’Olio said.

The future of fabrics

Ms Thompson said she was thrilled with CSIRO’s contribution to Worn Up.

“CSIRO’s Kick-Start Program allowed us access to global experts who could test and validate our assumptions about the viability of FABtec,” Ms Thompson said.

“We can now to go to market with the confidence that we’ve got a great product and potential investors can have the confidence that FABtec has the might of Australia’s national science agency behind it.

“CSIRO’s participation also helps us to overcome people’s misconceptions that waste isn’t as good as virgin materials. We really need to dispel that myth if we’re going to get serious about recycling in this country.”

Ms Thompson said she is currently seeking a local manufacturer to partner with so she can continue to work toward her vision of a waste-free world.

“We now have an amazing base formula that’s ready to be manufactured at a larger scale. FABtec has a plethora of potential uses from insulation to furniture to kitchen benches.

“We’ve had interest from manufacturers overseas, but we really want to see the work go to an Australian manufacturer.

“Not only will this keep work onshore, but it will help us to build the local infrastructure so we can establish a new supply chain and grow our national recycling capability.

“In the long-term I’d like to see the FABtec material deployed globally as an Australian product and the Worn Up operational model replicated around the world.”

Find out more about CSIRO’s Kick-Start program.