The challenge

A demand to produce more food

By 2050, the world will need to feed more than nine billion people. Major challenges facing humanity include limited fresh water, cropping systems that do not negatively impact the environment and the need to reduce or utilise farm production waste. Increased food and material production will need to come from existing or reduced cropping areas using reduced inputs. Overcoming these challenges means having to dramatically improve current practices.

Three areas of focus are required:

- Use of the same or less land to raise more crop.

- Improved efficiency of limited fresh water supplies.

- Reduced waste generation in agricultural practices.

War on plastics

Globally, over 300 million tons of plastics is manufactured annually. An estimated 70 per cent of all single use plastics, at some stage of their life cycle (whole, partially decomposed, or microplastic beads), end up polluting our terrestrial and aquatic ecosystems.

Plastic mulch films are used to, suppress weeds, increase soil temperature, reduce water evaporation, and improve the transpiration process during plant growth. 10 million tons of plastic mulch films are used in farming. This is expected to increase by 20 per cent annually, and none of this plastic is truly biodegradable. As a result, plastic debris accumulates in farm soils or landfill, or in the natural environment.

There are now long-term negative effects associated with the build-up of plastic mulch residues in soil, such as reduced porosity and water holding capacity, and toxic effects on plants such as leaf wilting, dead seedlings and premature ageing. All of which cause significant declines in farm productivity.

Our response

TranspiratiONal-SBM technology

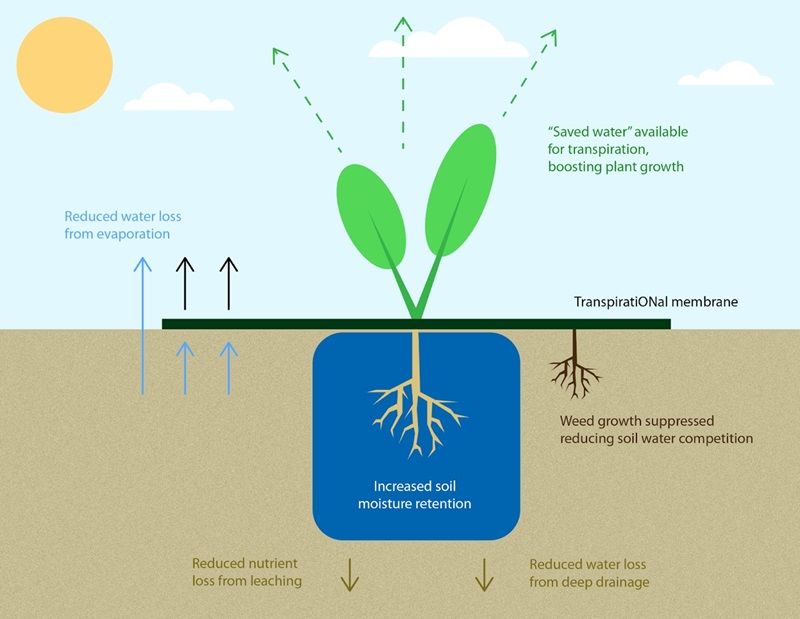

The TranspiratiONal membrane sits on the soil surface, acting as a barrier which leads to reduced water loss from evaporation. This results in increased soil moisture retention in the root zone, reduced nutrient loss from leaching, and reduced water loss from drainage. This makes "saved water" available for transpiration, boosting plant growth.

Illustrated diagram of how TranspiratiONal-SBM technology works

We have developed an innovative sprayable biodegradable membrane called TranspiratiONal-SBM. It allows farmers to control weeds, increase crop yields, and conserve water whilst eliminating the use of plastic mulch films. TranspiratiONal-SBM is sustainable farming without leaving an imprint on the environment.

TranspiratiONal-SBM allows for "spray and walk away" applications. Biodegradation rates of the membrane are 'tuneable' with the polymer substrate dispersing and breaking down naturally after the crop cycle with the help of the soil microbiome.

Using TranspiratiONal-SBM means there is no:

- Need for highly specialised farm equipment.

- Disposal of plastic mulch required after each cropping cycle.

- Toxic residues left in the soil.

How is TranspiratiONal-SBM is different from conventional plastic mulch films?

Features of TranspiratiONal-SBM makes it a more environmentally friendly and sustainable option for farmers.

| Conventional plastic mulch films | TranspiratiONal-SBM |

|---|---|

| Not biodegradable in fields | Completely biodegradable in fields |

| Degrades into fragments and microbead plastics with continual leaching of toxic additives and heavy metals | Breaks down completely into naturally occurring by-products such as gases, water, biomass and inorganic salts |

| Only suited to manually harvested row crops | Can be applied to manually or mechanically harvested row or broadacre crops |

| In place for entire growing season. Deteriorated fragments can harm microbiota and organisms, depleting organic matter and increasing water repellence | No negative impacts on soil or water systems, microbiota or soil organisms |

| Costly application using highly specialised machinery with limited flexibility | Simple and flexible application processes with farmers able to determine depth, thickness and width of the coverage using simple hand-held spray or conventional spray rig |

| Costly retrieval processes | No retrieval needed, breaks down completely into natural by-products |

| Wasteful dumping that requires incineration or buried in landfills | Breaks down into natural by-products |

The results

Water savings invested into crop growth

TranspiratiONal-SBM has been trialled in irrigated fields throughout Australia and on different soil types, from sandy loams through to heavy clays.

Crops tested using TranspiratiONal-SBM include:

- Cotton

- Sorghum

- Melons

- Tomatoes

Trials to date have confirmed improvements in water use efficiency, up to 30 per cent, and increased crop yields, while also maximising weed control.

The water savings in drought stricken climatic conditions can allow for more water to be accessible for other agricultural or environmental flows.

Further information

Whether you are an investor or customer, don't hesitate to contact the TranspiratiONal-SBM team with your queries:

Dr Stuart Gordon

Stuart.gordon@csiro.au

+61 40 777 9322

Scientific publications where SBM-TranspiratiONal was tested

- Braunack M.V. et al (2021) Evaluation of a sprayable biodegradable polymer membrane (SBPM) technology for soil water conservation in tomato and watermelon production systems. Agricultural Water Management 243 (2021) 106446

- Borrowman C.K. et al (2020) LC-MS analysis oof the degradation products of a sprayable, biodegradable poly(ester-urethan-urea). Polymer Degradation and Stability 178 (2020) 109218

- Braunack M.V. et al (2020) A sprayable biodegradable polymer membrane (SBPM) technology: effect of band width and application rate on water conservation and seedling emergence. Agricultural Water Management 230 (2020) 105900

- Braunack M.V. et al (2020) Initial experimental experience with a sprayable biodegradable polymer membrane (SBPM) technology in cotton. Agronomy 2020, 10, 584

- Filipovic V et al (2020) Sprayable biodegradable polymer membrane technology for cropping systems: Challenges and Opportunities. Environ. Sci. Technol. 2020, 54, 4709-4711

- Gu X et al (2020) Effects of degradable film mulching on crop yield and water use efficiency in China: A meta-analysis. Soil & Tillage Research 202 (2020) 104676

- Adhikari R et al (2019) Effect of viscosity modifiers on soil wicking and physio-chemical properties of polyurethane based sprayable biodegradable polymer membrane. Agriculture Water Management 222 (2019) 346-353

- Johnston P and Adhikari R (2017) Synthesis, properties and applications of degradable ionomers. European Polymer Journal 95 (2017) 138-160

- Adhikari R et al (2016) Preformed and sprayable polymeric mulch film to improve agricultural water use. Agricultural Water Management 169 (2016) 1-13